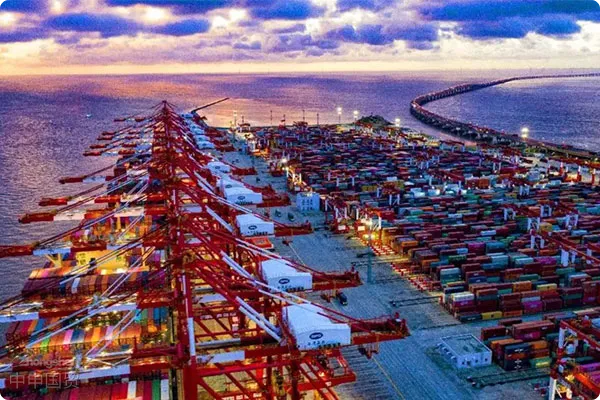

- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Semiconductorequipment. For example, Indonesia has the SNI certification, Thailand has the TISI certification, and the Philippines has the BPS certification. It is necessary to confirm in advance the equipment voltage (such as 380V/50Hz in Thailand), the compatibility of the CE certification, and the proof of environmentally friendly materials.Three Core Challenges

Against the backdrop of accelerated global semiconductor industry restructuring in 2025, Chinese enterprises equipment import demands exhibitrapid technological iteration, stringent regulatory requirements, and high logistics complexityas prominent characteristics. According to the latest customs statistics, precision semiconductor manufacturing equipment averages 37% longer clearance time than general industrial equipment, with tariff dispute occurrence rates 4.2 times higher than conventional goods.

Key Node Analysis of the Entire Import Process

Successful semiconductor equipment import requires mastering five core processes:

- Commodity classification verification

- HS code determination requires consideration of equipment technical parameters (such as wafer size, process precision)

- The 2025 edition of the Specialized Semiconductor Equipment Catalog adds classification guidelines for lithography machine components

- License preparation

- The application cycle for MOFCOMs Automatic Import License (O Certificate) has been shortened to 5 working days

- For equipment of US origin, an End-User Statement must be applied for in advance

- Transportation solution comparison

- Customs declaration strategy

- Accurate tax calculation

Practical experience in risk management

Our handled typical cases show that enterprises often fall into the following risk traps:

- Technical parameter misjudgmentResulting in classification errors (one company incurred 820,000 RMB in back taxes for failing to declare wafer transfer systems)

- It is recommended to verify through the following methods:Certificate deficiencyAffecting tariff preferences (imports of Japanese/Korean equipment require CO certificates authenticated by chambers of commerce)

- Logistics loss disputes(Precision equipment has 15% higher damage rate during transport compared to standard equipment)

- Exchange rate fluctuations eroding profits(USD/CNY exchange rate fluctuations reached 6.7% in 20251- May)

Transportation solution cost comparison model

- Maritime TransportationFCL solution

- Cost: $8500-$12000/40HQ

- Transit time: 35-45 days

- Applicable to: Large lithography machine components

- Air TransportationCharter flight solution

- Cost: $8.5-$12/kg

- Transit time: 3-7 days

- Applicable to: Emergency spare parts transportation

- China-Europe Railway ExpressSolution

- Cost: $6500-$9000/container

- Transit time: 18-22 days

- Applicable: Import of German equipment

Professional agency service selection criteria

EvaluationImport RepresentationCompanies should focus on three dimensions:

- Industry experience indicators

- ≥50 semiconductor equipment operation cases in the past three years

- Hold AEO Advanced Certification qualification

- Service network capability

- Have branches in the equipments country of origin

- Equipped with professional anti-vibration transport fleet

- Value-added service capability

- Provide full-process supervision for equipment installation and debugging

- Develop intelligent logistics monitoring system

2025 operation practice recommendations

In response to the latest regulatory developments, companies are advised to focus on:

- Prepare 6 months in advanceEquipment technical review documents(New special review for nano-level equipment starting from 2025)

- Utilize under RCEP agreementTariff concession rules(Etching equipment made in Japan tariff rate reduced to 3.2%)

- EstablishEmergency customs clearance plan(Recommended to reserve 15% of cargo value as security deposit)

Success case insights

A wafer manufacturing company achieved through professional agency services:

- Equipment transport damage rate reduced from 8% to 0.3%

- 24% reduction in comprehensive logistics costs

- Customs declaration error rate reduced to zero

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912